In brief: Solid-state batteries promise to be a game-changer for electric vehicles, but they’ve remained stubbornly out of reach. That, however, may change sooner than expected as Stellantis throws its weight behind a battery startup called Factorial.

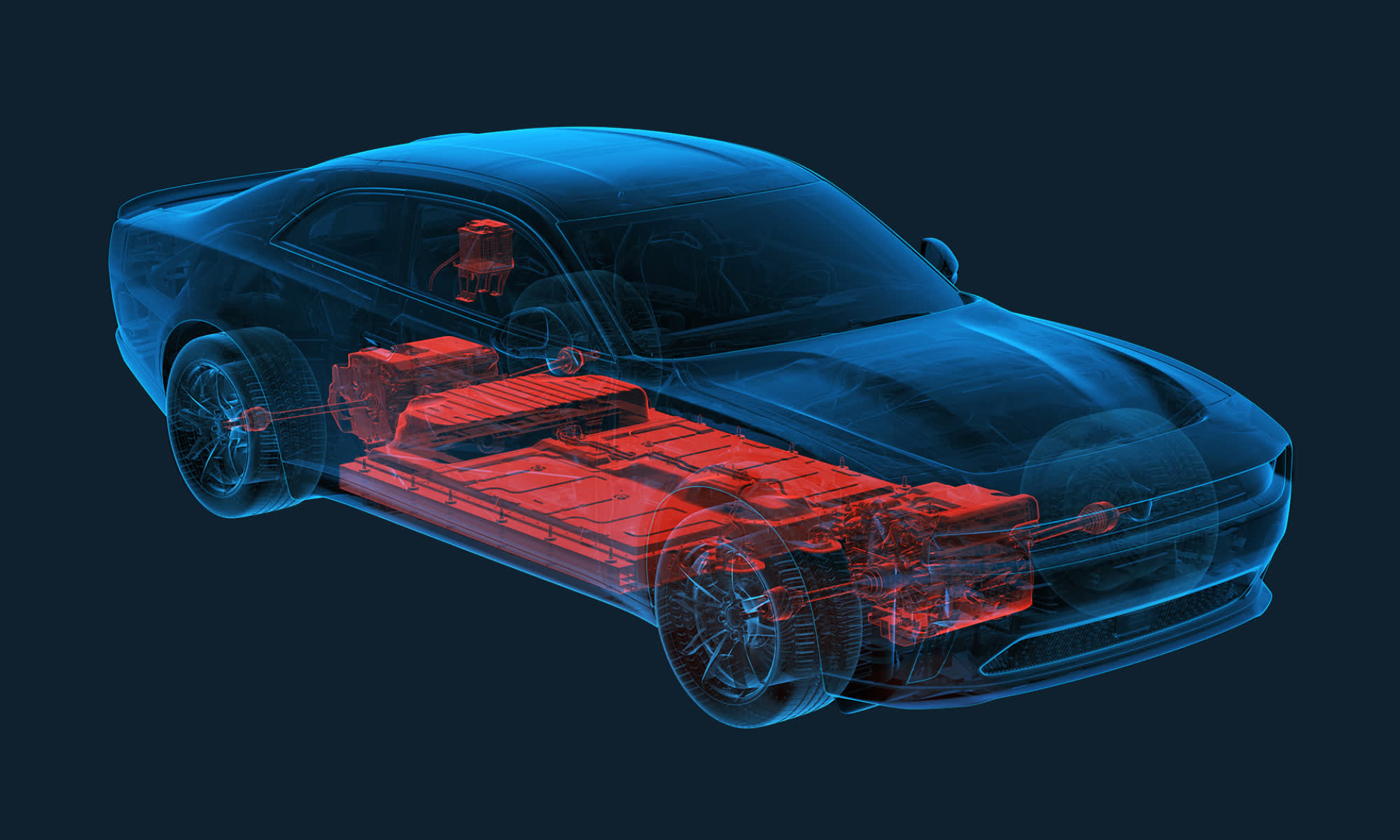

The automaker recently announced plans to test semi-solid-state battery cells from Factorial in a fleet of Dodge Charger Daytona electric sedans by 2026. This is significant, considering that most other battery manufacturers are not expected to start mass-producing solid-state cells for electric vehicles until the end of this decade.

The race to develop solid-state batteries is driven by their thermal stability and energy density. Factorial claims that its proprietary FEST (Factorial Electrolyte System Technology) cells can achieve 391 watt-hours per kilogram at the cell level. This density is significantly higher than today’s best lithium-ion cells, which typically range from 200 to 300 Wh/kg. When applied to EV pack levels, the tech could enable substantially longer ranges or allow for smaller battery packs that improve efficiency.

Additionally, there are other potential benefits, such as charging speeds that are up to 50 percent faster, lighter weight construction, and enhanced safety (solid electrolytes are non-flammable compared to liquid-based chemistries).

However, there’s a catch, and it’s a significant one: Factorial’s cells aren’t a pure solid-state design. They still rely on liquid electrolytes working in tandem with solid components, resulting in a hybrid semi-solid approach. Stellantis believes this will provide many of the advantages of solid-state batteries without the exorbitant costs and manufacturing challenges associated with a true all-solid battery.

The advantage for Stellantis is that Factorial’s cells can potentially be produced on existing fabrication lines. Factorial states that its solid-state units offer “drop-in compatibility with existing lithium-ion battery manufacturing infrastructure,” making it easier to scale up production without the need to build dedicated factories from scratch.

“This demonstration fleet is an important milestone in our partnership with Factorial,” said Ned Curic, Stellantis’ chief engineering and technology officer. “By integrating Factorial’s innovative battery solution into the STLA Large platform, we are validating its potential to enhance our electric vehicle lineup, ensuring customers benefit from improved performance, longer driving ranges and faster charging times in the coming years.”

Of course, the real test will come when Stellantis’ solid-state Chargers hit the streets. Durability and safety over thousands of charging cycles will need to be proven, and costs will need to be justifiable at scale. But if everything comes together, Stellantis could gain a serious competitive edge.

That said, Stellantis isn’t exactly leaving its rivals in the dust just yet. Mercedes, another investor in Factorial, has stated that it will incorporate the startup’s semi-solid-state technology into its own EVs by 2026. Additionally, Hyundai and Kia – both backers of Factorial – are also developing solid-state batteries in collaboration with the company.