Choose your answer and the correct choice will be revealed.

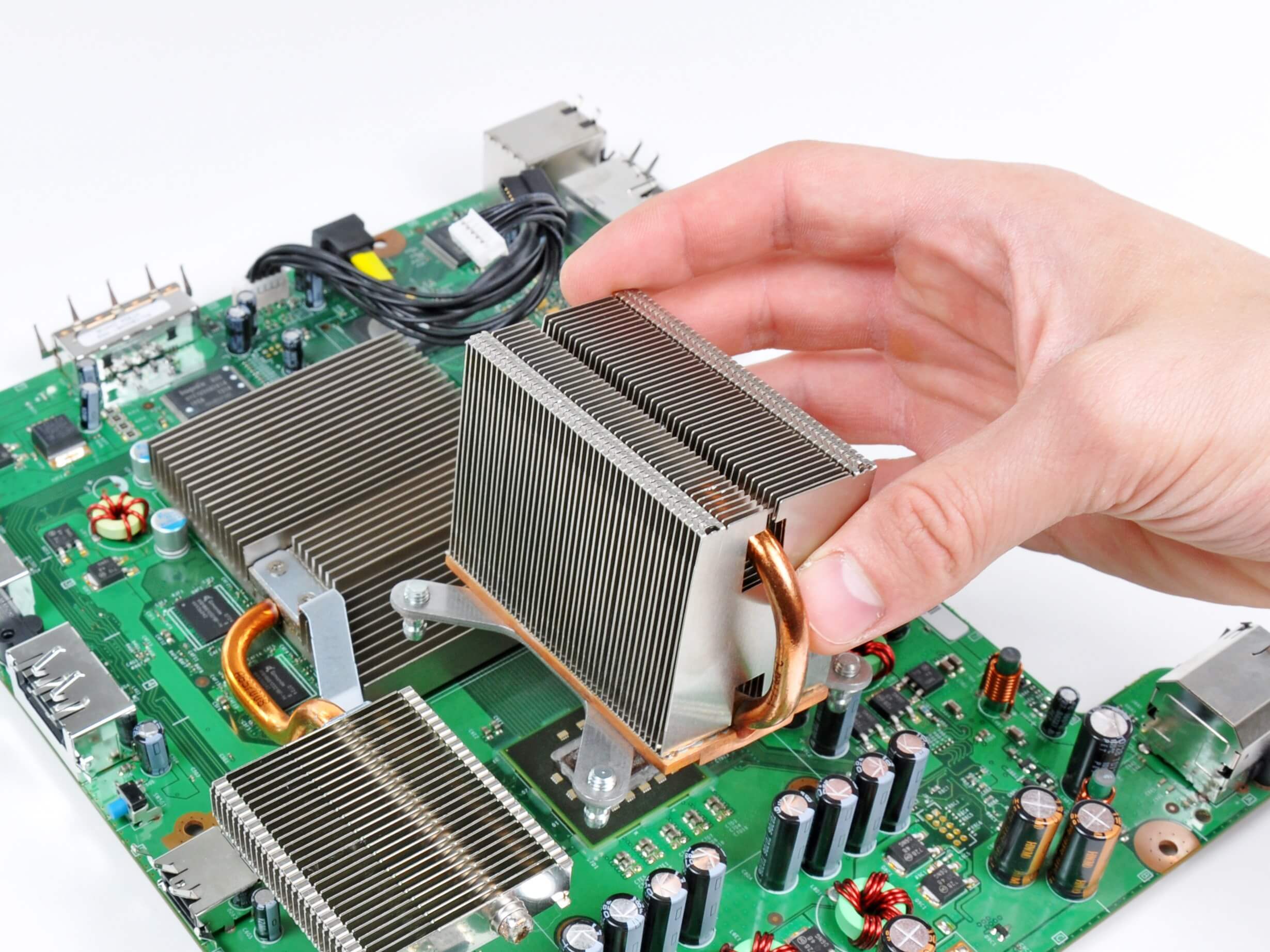

Aluminum and copper have the highest thermal conductivity among common metals (205W/mK and 401W/mK versus say 50W/mK for steel) and are easily the most frequently used materials in the making of computer heatsinks. Although copper is superior at conducting heat, aluminum performs respectably while being cheaper, lighter and easier for manufacturers to work with.

There are better heat conductors but they aren’t practical materials for producing computer heatsinks: silver exceeds copper’s thermal conductivity at 429W/mK (hence Arctic Silver thermal paste), diamond brings that into the thousands at 2300W/mK (and likewise hence IC Diamond thermal paste), while early measurements of graphene puts it at 5300W/mK. Less popularly, graphite has also been used in the production of PC heatsinks when a manufacturer wants something lighter than both copper and aluminum with thermals that land in between.

Diamond is a remarkable material in terms of thermal conductivity, topping the list at an estimated 2,200 to 2,500 W/mK. However, the cost and difficulty of producing large, pure diamond structures make it an impractical choice for mass-produced heatsinks. Silver is the best metallic conductor of heat, with a thermal conductivity of about 430 W/mK. This property makes silver an attractive option for heatsinks. However, like diamond, silver is expensive and not typically used in mass-market cooling solutions. Furthermore, its softer nature compared to other metals could potentially lead to durability issues in the long term.

With a thermal conductivity of 400 W/mK, copper is another excellent heat conductor. It’s less expensive than silver and stronger too, offering better durability. Copper’s high density allows for more efficient heat absorption and dissipation, making it an ideal choice for heatsinks. However, it’s heavier than aluminum, and this weight issue can be a drawback in some applications, such as laptops or small form factor (SFF) PCs.

Aluminum is the most commonly used material for heatsinks due to its balance of cost, weight, and thermal conductivity (around 205 W/mK). Although it doesn’t conduct heat as well as copper or silver, aluminum is lightweight and easy to shape, providing excellent cooling performance for the cost. Its corrosion resistance also adds to its longevity, making it a preferred choice for many manufacturers.

The choice of heatsink material often comes down to a balance between thermal conductivity, weight, durability, and cost.