The big picture: At its Foundry Direct Connect event last week, Intel announced a new public roadmap, revealing that its 14A foundry node (1.4nm class) will go into production in 2026 before being scaled up the following year. The company has now also confirmed that it will start developing its 10A node (1nm equivalent) in late 2027.

Intel 14A will succeed the 18A and 20A nodes, but the company also says that it will introduce an improved version, dubbed 14A-E, in 2027. Chipzilla, however, did not offer details about how it will differ from the standard 14A. As for 10A, the company did not reveal much about this node either, but did claim that it will bring “double-digit” improvements in power efficiency and performance over previous generations.

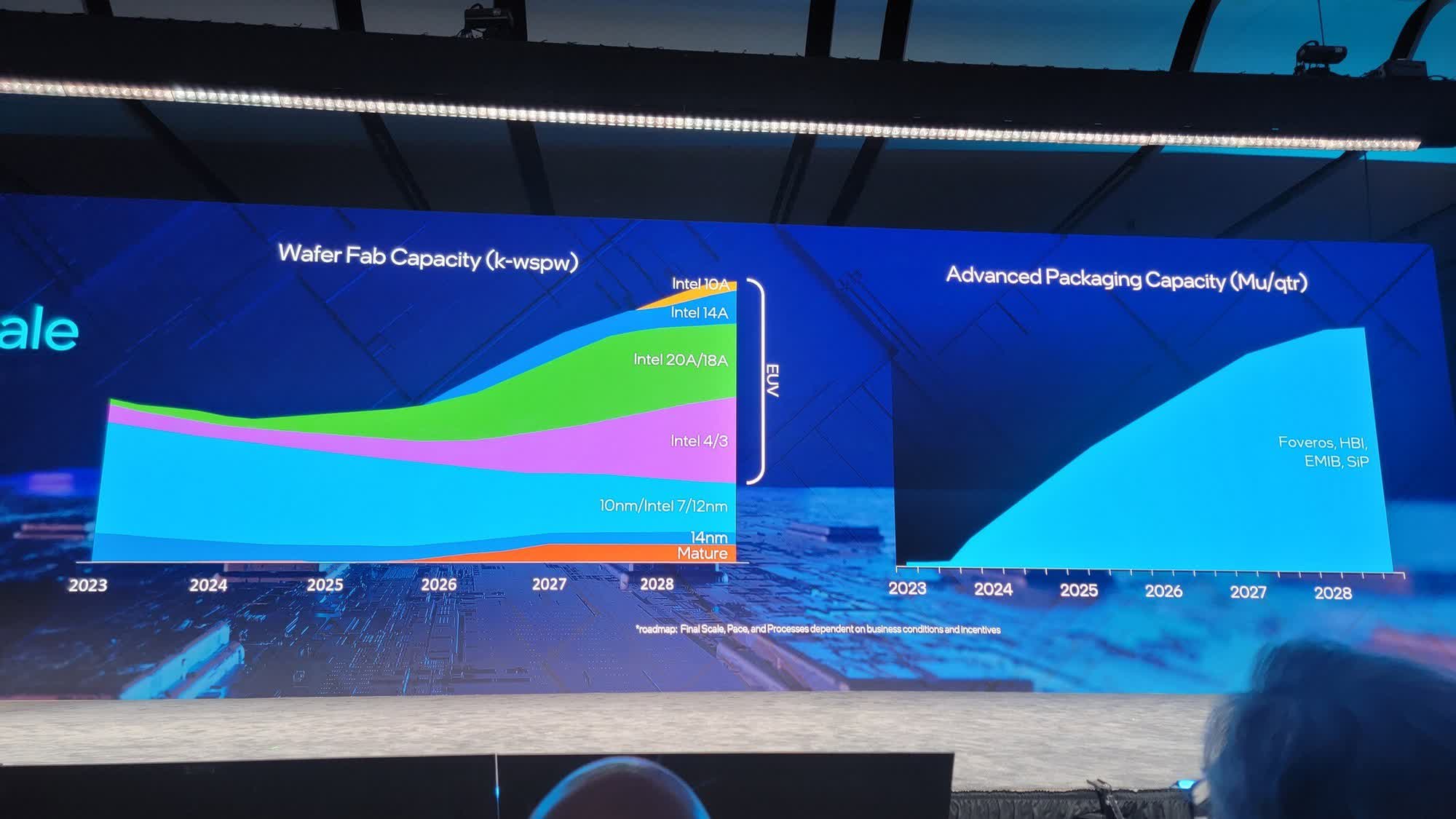

Speaking to Tom’s Hardware, Intel’s Foundry Manufacturing and Supply GM Keyvan Esfarjani also revealed plans to incorporate high-NA-EUV machines from ASML to produce smaller transistors. It is part of the company’s plans to transition to EUV (extreme ultraviolet lithography) technology and phase out older manufacturing processes. With demand expected to increase in the coming years, Intel is also planning to expand capacity and use advanced packaging techniques, especially for AI accelerators.

Currently, Intel 4, Intel 3, and Intel 20A are the only three fabs that use EUV. Between them, they reportedly make up about 15 percent of the company’s total wafers by volume, while most of the capacity is still hogged by the DUV-based Intel 7. However, that is slated to change in the near future, with the company expecting EUV-based nodes to continue growing through 2025.

According to Intel, wafer volumes of 20A and 18A are expected to exceed those of the Intel 4 and Intel 3 by next year, while by 2026, the company plans to push out twice as many 20A/18A wafers as Intel 4 and Intel 3. Do note that despite using EUV tech, Intel 4 and Intel 3 are still stuck with FinFET transistors for the final nodes even as the company is transitioning to nanosheets, or RibbonFET, with 20A.

Finally, Intel also announced plans to introduce collaborative robots, or “cobots,” to automate the manufacturing process in its foundries. According to the company, these devices will work alongside humans as part of the next wave of factory automation.